Services

CNC Milling/Turning

High capacity on-demand CNC milling services for rapid prototypes and production parts, Various CNC – turned metal and plastic part options are available

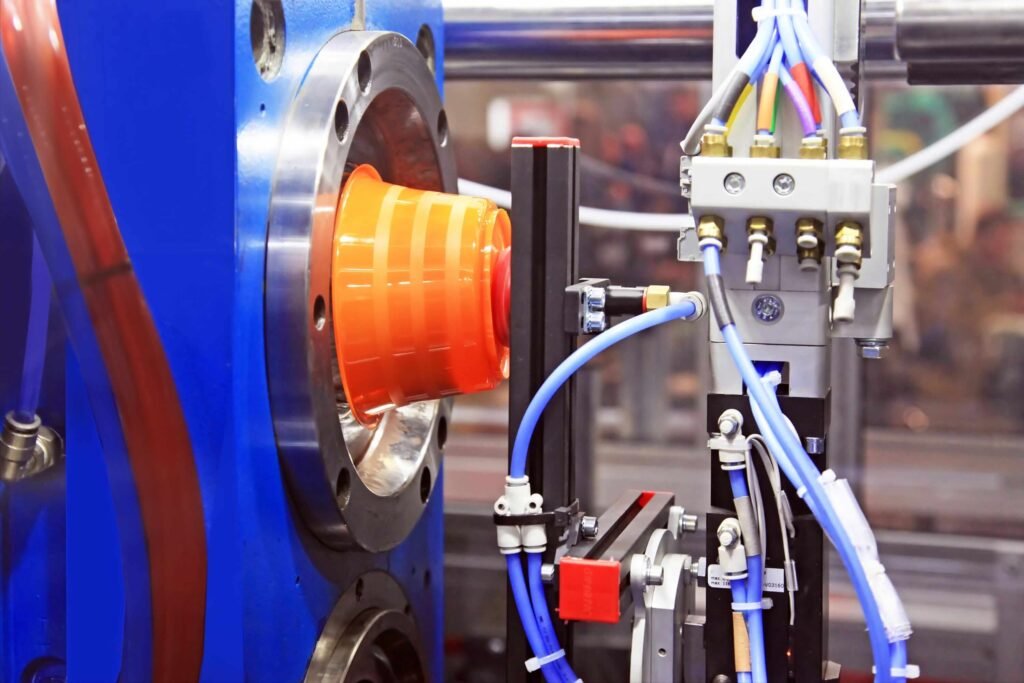

Injection Molding

We have domestic and imported tooling from Switzerland and Japan.

Kinge’s assembly service provides a reliable and cost-effective solution for customers who require through-hole component assembly for their electronic products.

Sheet Metal

Sheet metal is a kind of technology to bending or pressing as the 3D drawings. There are many standard thickness materials like Aluminum, steel, spring steel, copper etc.

Vacuum Casting

Vacuum casting technology is an advanced manufacturing process that can produce high-precision, high-quality parts and products. Vacuum casting technology is a process in which thermoplastic materials are heated and softened to form the desired shape on the surface of the mold county by vacuum adsorption.